SERVICES

Polymers made responsibly.

Globally, Ravago Manufacturing Group of Companies has perfected the technology to customize compounds of thermoplastic resin using prime and reprocessed based materials.

RMI offers a unique and systematic array of facilities that consist of modern equipment, experienced polymer technologists and adequate capacity to meet the demands of customers’ requirements.

At RMI, we replicate the technology and good practices along with manufacturing infrastructure required to offer consistent quality of finished products.

With an annual capacity of more than 14,000 MT, we share our capacities between tolling and producing our own grades. These tailor-made compounds suit the exacting needs of the application which are in compliance with Ravago standards and their quality is verified under ASTM & ISO standards.

Our tolling division is equipped to serve global as well as domestic partners for their tolling needs of engineering thermoplastic compounds.

Our team offers extensive knowledge and are abreast to the engineering techniques to provide our partners with quality tolling services. With a robust production line, we manage mass polymer production for customers in varying industries.

We have developed strategic partnerships across the world catering to their manufacturing needs. Our reliable quality team cross-checks the product attributes at every step of the process so that it meets the desired outcome.

By our commitment, we maintain utmost responsibility to ensure the safety and confidentiality of intellectual property rights owned by our esteemed tolling partners.

With years of experience in recycling plastic waste, the Ravago team has been offering their systems and technology to handle, clean, and process plastic scrap and in turn, supply a quality consistent product mix to various customers.

We provide unique and viable solutions to stakeholders involved in the chain of generating, converting and re-using plastic.

Our contribution to national development is through a closed-loop recycling programme that offers back to back pick-up of scrap generated at the source. This allows us to recycle polymer waste and put them back into mainstream industrial applications.

Below is a list of plastic scrap that we can recycle:

- Nylon yarn to granules

- Recycling of rigid plastics like battery boxes, drums, crates, pales (PP,PE, LLDPE)

- Recycling of soft plastics like films, sheets (PP,PE, PC)

- Recycling of polymer waste from Petrochemical plants; PE and PP lumps, powders, floor sweeps…

- Recycling of PE Wax

- Recycling of ABS, PC and PA lumps (and post-industrial waste)

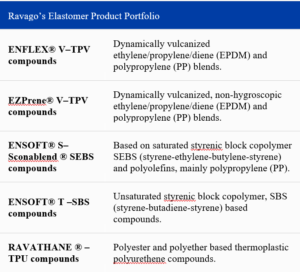

Thermoplastic elastomer is the composition of properties that belong to thermoplastics and elastomers with advantages of plastic and rubber materials. Elastomer is often used because of the high flexibility (to stretch and return to its original shape) and longer life span it offers. They are widely used to modify the properties of rigid thermoplastics, usually improving their impact strength.

The wealth of applications of elastomers range throughout a pool of industries such as automotive, construction, consumer goods, home appliances, and electrical applications.

Ravago Manufacturing India work in close coordination with the global Ravago team to service and deliver thermoplastic elastomer requirements across the world.